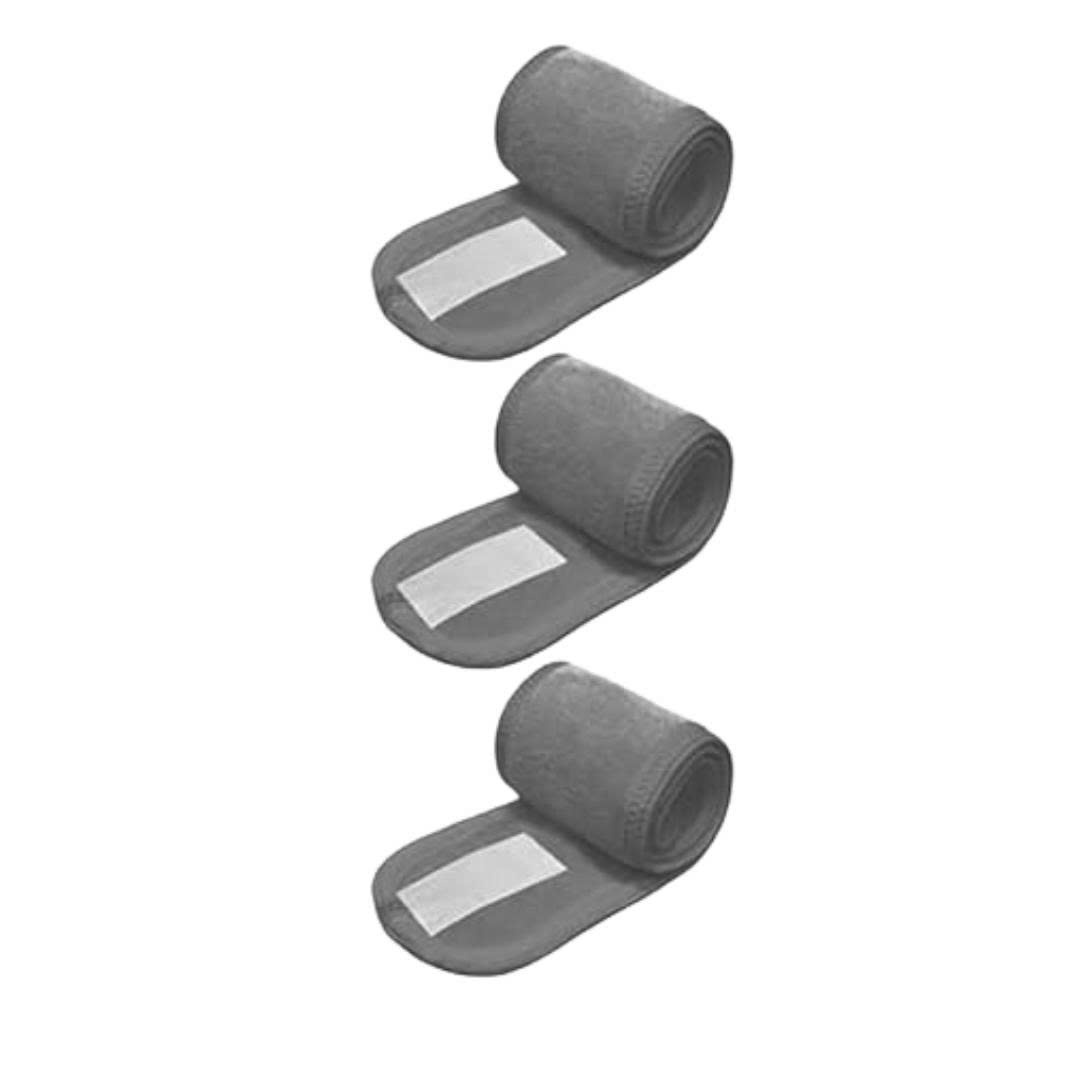

Headband

JESMARY - Vietnam Headband Factory: Rapid Prototyping, Flawless Execution

Contact

Quantity

Contact a consultant: 0357.118.508 - 0977.856.794 - 0971.026.205

Product information

In the export business, understanding the production process is key to building trust. At JESMARY, the Vietnam Headband Factory, we not only commit to High Quality and Reasonable Prices but also ensure transparency at every step. We are proud to present our 6-step process, optimized for speed and finesse across all export headband orders.

JESMARY’s 6-Step Headband Production Process

Our process is designed to transform ideas into a finished headband quickly and precisely.

Step 1: Idea Reception & Rapid Prototyping

Input: We receive technical drawings, physical samples, or concept images from the client.

Execution: Our dedicated R&D team analyzes the material and structure. A test prototype is manufactured quickly (often within a few days) to confirm the design, material, and printing/embroidery technique. This step ensures we catch trends without wasting time.

Step 2: Selection & Control of Premium Raw Materials

Materials: Once the sample is approved, we procure bulk materials. JESMARY prioritizes fabrics and accessory components (adhesives, threads, beads) certified for safety, such as Oeko-Tex Standard 100 or REACH.

Incoming Quality Control (IQC): Raw materials are rigorously inspected for colorfastness, elasticity, and chemical safety before entering production.

Step 3: Precision Cutting & Initial Processing

Laser/Automatic Cutting: Fabric is cut using modern machinery to ensure absolute precision, especially crucial for velvet headbands or complex designs.

Detail Preparation: Preliminary steps like logo embroidery, heat transfer printing, or stamping are executed to ensure logos and patterns are perfectly set.

Step 4: Sewing & Flawless Finishing (Flawless Execution)

Specialized Production Line: Skilled tailors assemble the components. For fashion headbands or handcrafted Vintage/Bohemian designs, we utilize a separate team of artisans to ensure meticulousness and durability.

In-Process Quality Control (IPQC): Quality checks are performed between sewing stages to detect flaws early, ensuring consistent export quality.

Step 5: Final Quality Control Inspection

Comprehensive Review: The finished headbands are subjected to a final inspection for size accuracy, finishing quality, secure fasteners/attachments, and cleanliness.

AQL Standards: Large batches are inspected according to the Acceptable Quality Limit (AQL) standards required by the client before packaging.

Step 6: Professional Packaging & Export Shipping

Custom Packaging: We support packaging tailored to the brand's specific requirements (hang tags, custom logo zip bags, etc.).

Logistics Commitment: JESMARY's logistics department handles all customs procedures and coordinates with carriers to ensure On-Time Delivery, maintaining your international business schedule.

JESMARY – Your Reliable Partner for All Headband Orders

JESMARY's transparent process and commitment to quality at every step serve as the strongest guarantee of reliability.

Contact us today to discuss your production process in detail and receive a preferential quote for your first export order!

CONTACT CONSULTATION AND ORDER

JESMARY group

Phone: 0357.118.508 - 0977.856.794 - 0971.026.205

Email: sales.jesmary@gmail.com

Show room: 193/9/2B Nguyen Thi Bup Street, Tan Chanh Hiep Ward, District 12, Ho Chi Minh City

Website: jesmary.net - jesmary.com - khanviet.net