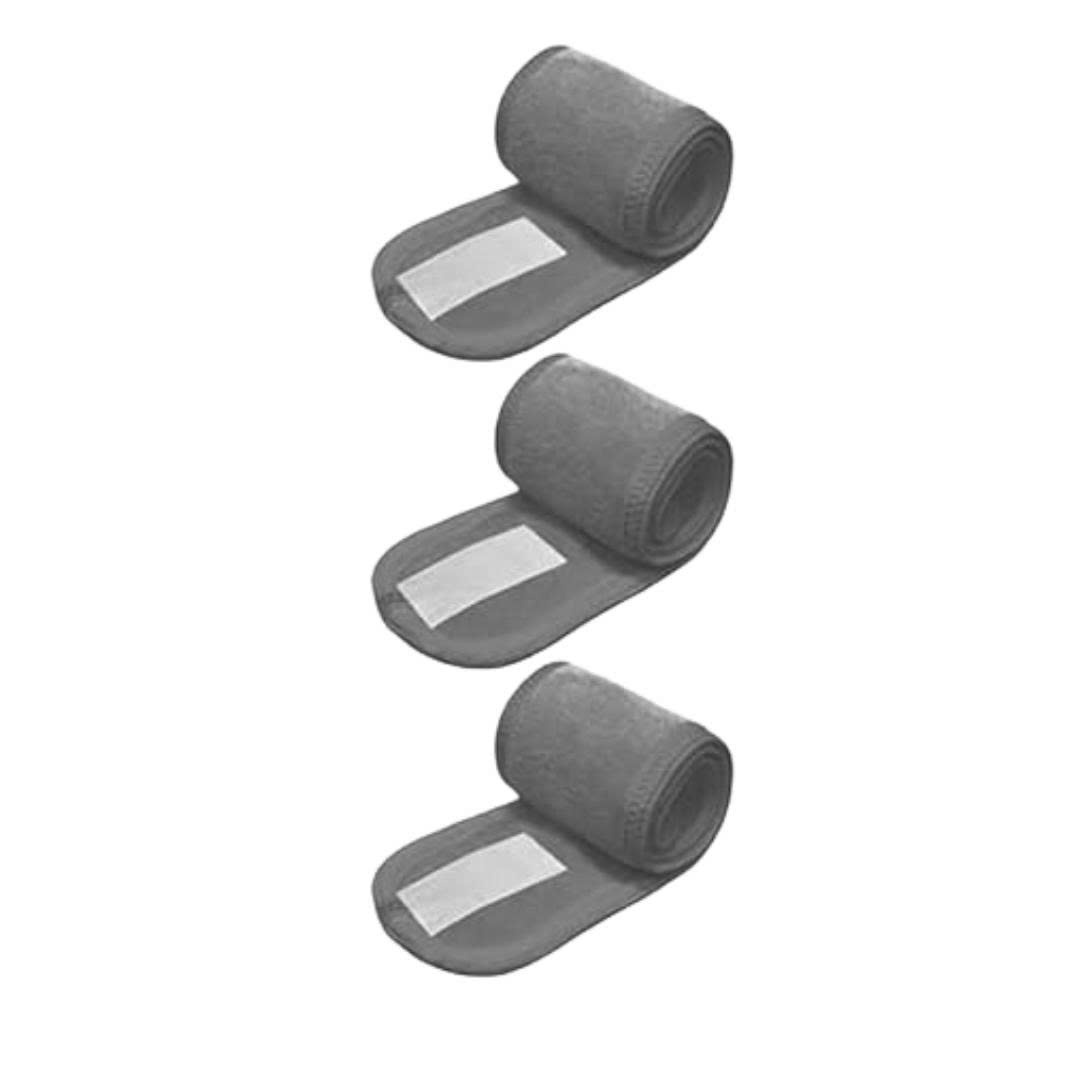

Headband

JESMARY - Diverse Headband Designs for Your Store

Contact

Quantity

Contact a consultant: 0357.118.508 - 0977.856.794 - 0971.026.205

Product information

The Standard Headband Manufacturing Process: The Secret to Creating High-Quality Headbands!

Are you passionate about the Headband business or interested in learning about the origins of these wonderful beauty accessories? Understanding the Headband manufacturing process is a prerequisite for ensuring the quality, uniqueness, and profitability of your products.

I. Stage 1: Concept, Design, and Material Preparation

This stage lays the foundation for the quality and styling of the Headband.

Design Blueprint: Clearly define the style, size, and standard curvature. The design must align with current trends and the target customer demographic.

Primary Material Selection: This step is crucial for determining quality. Factories select appropriate fabrics:

Silk/Satin: Used for elegant, fashion headbands.

Cotton/Elastic: Used for sports headbands.

Velvet: Used for winter headbands or party wear.

Accessory Preparation: Includes plastic/metal frames, elastic bands, padding foam, and decorative details like pearls and stones.

II. Stage 2: Cutting and Basic Processing

Raw materials are converted into components ready for assembly.

Precise Fabric Cutting: Fabric is cut using specialized machiner according to the approved pattern. This ensures accuracy and uniformity for bulk Headband orders.

Frame Cutting and Smoothing: For Alice bands, the hard frames are cut to size, and the edges are carefully smoothed to ensure safety and prevent discomfort or damage to the scalp during use.

Padding Preparation: Foam inserts are cut and shaped for thick headbands to create the necessary fashionable volume.

III. Stage 3: Sewing and Final Assembly

This stage requires meticulous care and specialized sewing techniques to create the finished Headband.

Sewing the Headband Cover: The fabric cover is sewn, turned right-side out, and shaped to create pleats, twists, or knots according to the design.

Frame Insertion and Fixation: The hard frame is gently inserted into the sewn cover. The cover is then hand-stitched or sealed with specialized glue at both ends to securely fix the frame, preventing the Headband from slipping out.

Elastic Attachment: Standard-elastic bands are sewn discreetly inside, ensuring the Headband fits snugly and comfortably without leaving marks.

IV. Stage 4: Embellishment and Quality Control

This step enhances the value and ensures the reputation of the Headband.

Accessory Embellishment: Artisans attach pearls, crystals, or bows by hand. This process requires skill to ensure the decorative elements are secure and evenly placed.

Quality Control: Every Headband undergoes rigorous inspection for:

Seam durability and security of attached elements.

Cleanliness.

Consistent size and color according to the approved sample.

Ironing/Heat Pressing: High-end Headbands, especially silk, are lightly ironed to maintain smoothness and aesthetics.

V. Stage 5: Packaging and Distribution

The final step in getting the Headband from the factory to the consumer.

Individual Packaging: Headbands are wrapped in clear plastic bags or branded boxes for optimal protection.

Boxing and Labeling: Products are sorted and packed into large cartons, ready for shipping.

Conclusion & Production Contact

Choosing a Headband production factory with a clear, professional process will help you control costs, guarantee quality, and build a reputable hair accessory brand in the market.

JESMARY is proud to be a long-standing Headband manufacturing partner, committed to a strict production process, ensuring every product meets the highest standards of aesthetics and durability. Contact JESMARY now to receive a detailed quote and realize your exclusive Headband ideas!

CONTACT CONSULTATION AND ORDER

JESMARY group

Phone: 0357.118.508 - 0977.856.794 - 0971.026.205

Email: sales.jesmary@gmail.com

Show room: 193/9/2B Nguyen Thi Bup Street, Tan Chanh Hiep Ward, District 12, Ho Chi Minh City

Website: jesmary.net - jesmary.com - khanviet.net