Headband

JESMARY – Tet Headband Manufacturer: Exclusive, Trend-Driven Designs Guaranteed

Contact

Quantity

Contact a consultant: 0357.118.508 - 0977.856.794 - 0971.026.205

Product information

JESMARY – Tet Headband Manufacturer: Exclusive Designs, Trend-Focused, With a Professional Production Process

During the Tet season, red–gold headbands, glitter designs, and festive decorative headbands are always among the best-selling accessories for shops, studios, and corporate gift programs. To create beautiful, durable, and trend-led products, JESMARY applies a professional, closed-loop headband manufacturing process — optimized for precision and quality.

Below is an in-depth look at the Tet headband production process at JESMARY, explaining why we are the trusted partner of hundreds of shops each festive season.

1. Concept Development – Designing Exclusive Tet Collections

At JESMARY, every Tet headband begins with careful research:

Tracking yearly Tet trends: key colors, hot motifs (peach blossoms, apricot blossoms, zodiac animals, red bows, glitter).

Creating exclusive designs to minimize market duplication.

2D/3D sketching and selecting materials suitable for each structure.

Ensuring shops receive trendy, unique, and high-demand products.

2. Material Selection – Durable, Beautiful, and Safe

JESMARY prioritizes high-quality materials:

Premium flexible plastic frames that are comfortable and gentle on the ears.

Felt, ribbon, glitter fabric, velvet… all checked for colorfastness and durability.

Grade-A adhesive, threads, and decorative accessories — safe and non-irritating.

Ensuring the headbands are long-lasting, sturdy, and resistant to peeling.

3. Manufacturing & Handcrafting – Precision in Every Detail

This is the most crucial stage, consisting of 5 main steps:

Step 1: Forming the Headband Base

Frames are pre-shaped according to the design.

Checked for flexibility, elasticity, and resistance to bending.

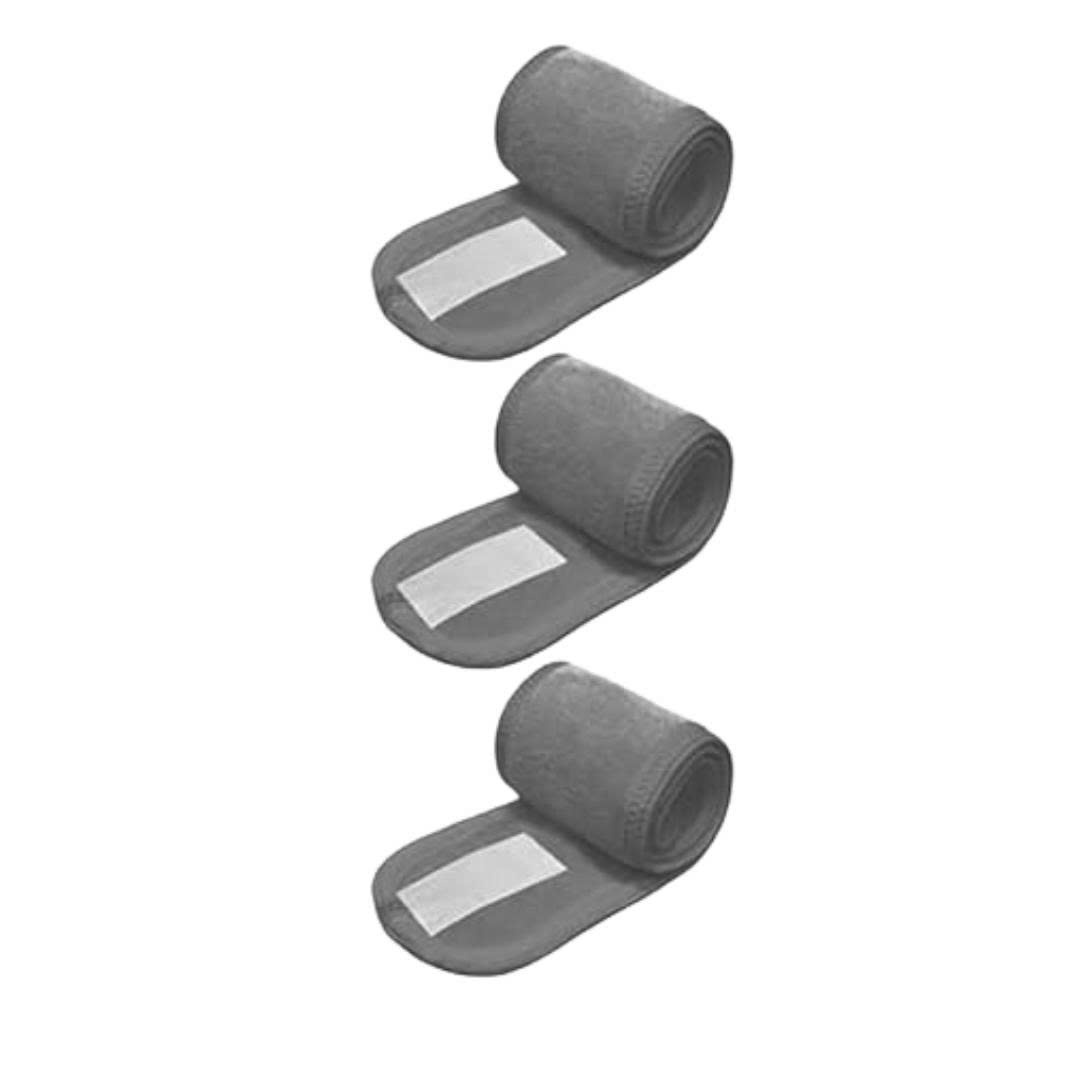

Step 2: Wrapping the Band

Skilled workers wrap each frame by hand to keep the fabric smooth and wrinkle-free.

All seams are neatly finished — no glue marks, no rough edges.

Step 3: Cutting & Attaching Decorations

Tet letters, flowers, bows, numbers, and zodiac motifs are cut with precision machines.

Decorations are attached manually or semi-automatically to ensure perfect symmetry and stability.

Step 4: Stitching or Gluing for Reinforcement

Some models are lightly stitched to increase durability.

Industrial-grade adhesives are used to prevent detachment.

Step 5: Final Quality Check

Each headband is inspected for firmness, symmetry, adhesion, and aesthetics.

100% of defective pieces are removed.

Result: high-quality, consistent, and visually appealing Tet headbands.

4. High Production Capacity – Fast Turnaround for Large Orders

JESMARY offers:

A large workshop with experienced craftsmen.

Flexible capacity from 500 to 50,000 units per batch.

Optimized workflow to meet Tet peak season demand.

Guaranteed on-time delivery, correct quantity, correct design.

5. Packaging – Shipping – Sales Support for Shops

We support partners with:

Clean, secure, aesthetically pleasing packaging.

Nationwide fast delivery.

Custom logo, private-label, and exclusive design services.

Recommendations on best-selling Tet styles and trending combos.

Why Choose JESMARY?

Exclusive, trend-driven designs

Professional and detailed production workflow

Factory-direct pricing with high profit margins

Stable, premium product quality

Fast, reliable service during peak Tet season

CONTACT CONSULTATION AND ORDER

JESMARY group

Phone: 0357.118.508 - 0977.856.794 - 0971.026.205

Email: sales.jesmary@gmail.com

Show room: 193/9/2B Nguyen Thi Bup Street, Tan Chanh Hiep Ward, District 12, Ho Chi Minh City

Website: jesmary.net - jesmary.com - khanviet.net